swiss cnc machine programming

Applying the right tools and technique to CNC part programming will let shops get the most out of their multitasking. Check out the list of G-codes in CNC machining.

The Art of CNC Swiss Machining.

. G00 Rapid positioning. G01 Linear interpolation. Blackstone Swiss Engineering is committed to providing technical support and engineering services to the Swiss machining industry in a cost effective way.

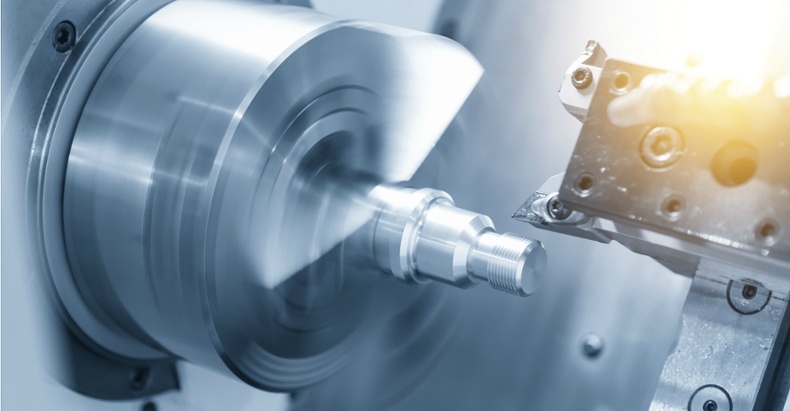

A CNC Swiss-type lathe is capable of turning milling and threading to drop complex parts complete. Specialized programming on CNC machines can be utilized to optimize processes. Programming CNC Swiss Lathe For Maximum Efficiency.

CNC Swiss Programming is a little science mixed in with the creative art of developing a process that produces perfect parts and our programmers all have. G02 Circular interpolation clockwise. Easy to learn and use in a short amount of time.

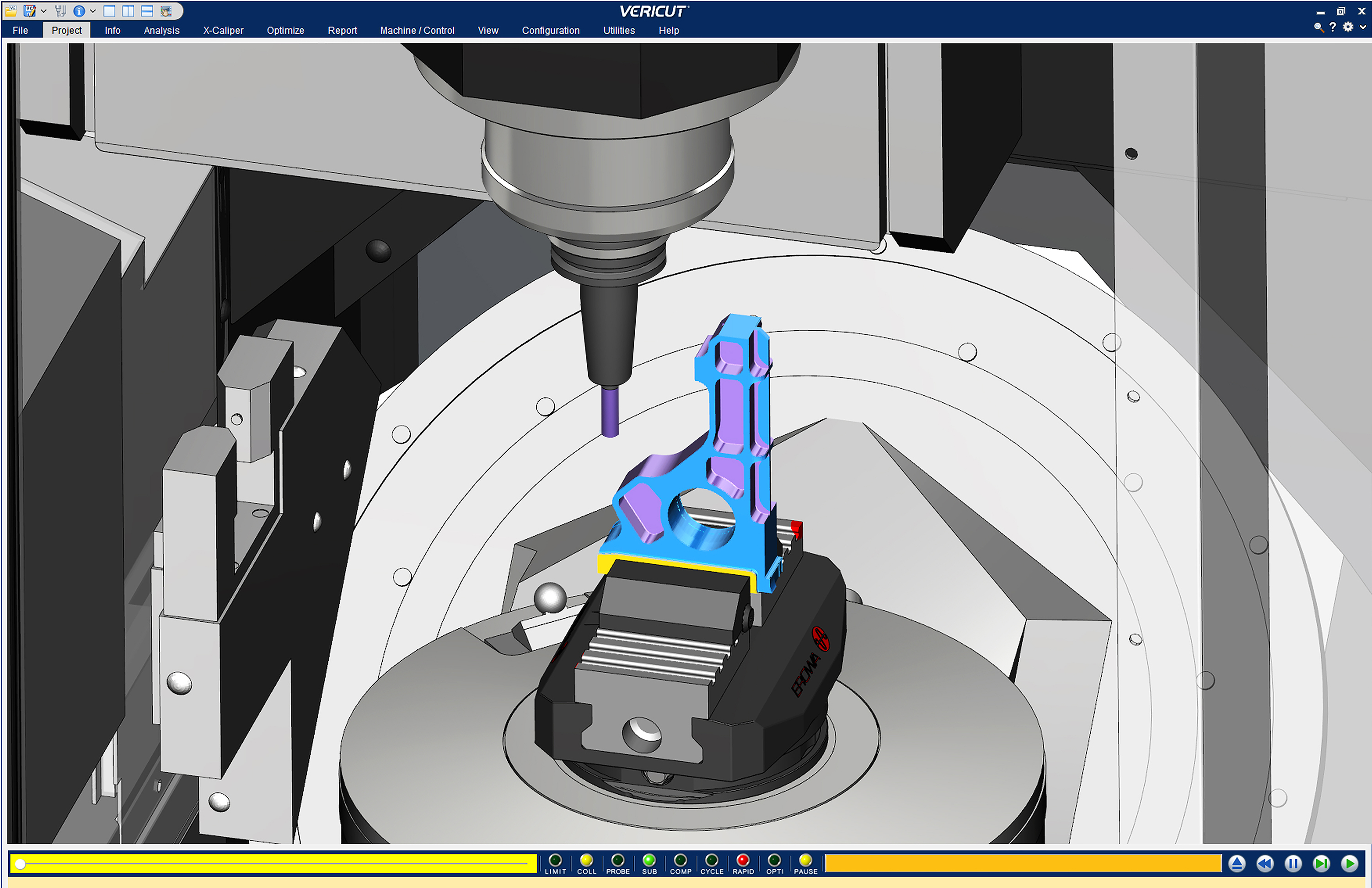

PartMaker is the leader in Swiss programming because its purpose built for your complex machines and excels in these areas. Over the years programming of Swiss machines has also gotten easier. G03 Circular interpolation.

Up to 7 cash back Swiss machining software allows you to program your multi-axis and sliding headstock Swiss lathes easily. The Workday of a Computer Numerical Controller Swiss-Style Lathes The Swiss-type machine of Groth Manufacturing Swiss Screw Machines The National Institute for. 10 hour shift 3.

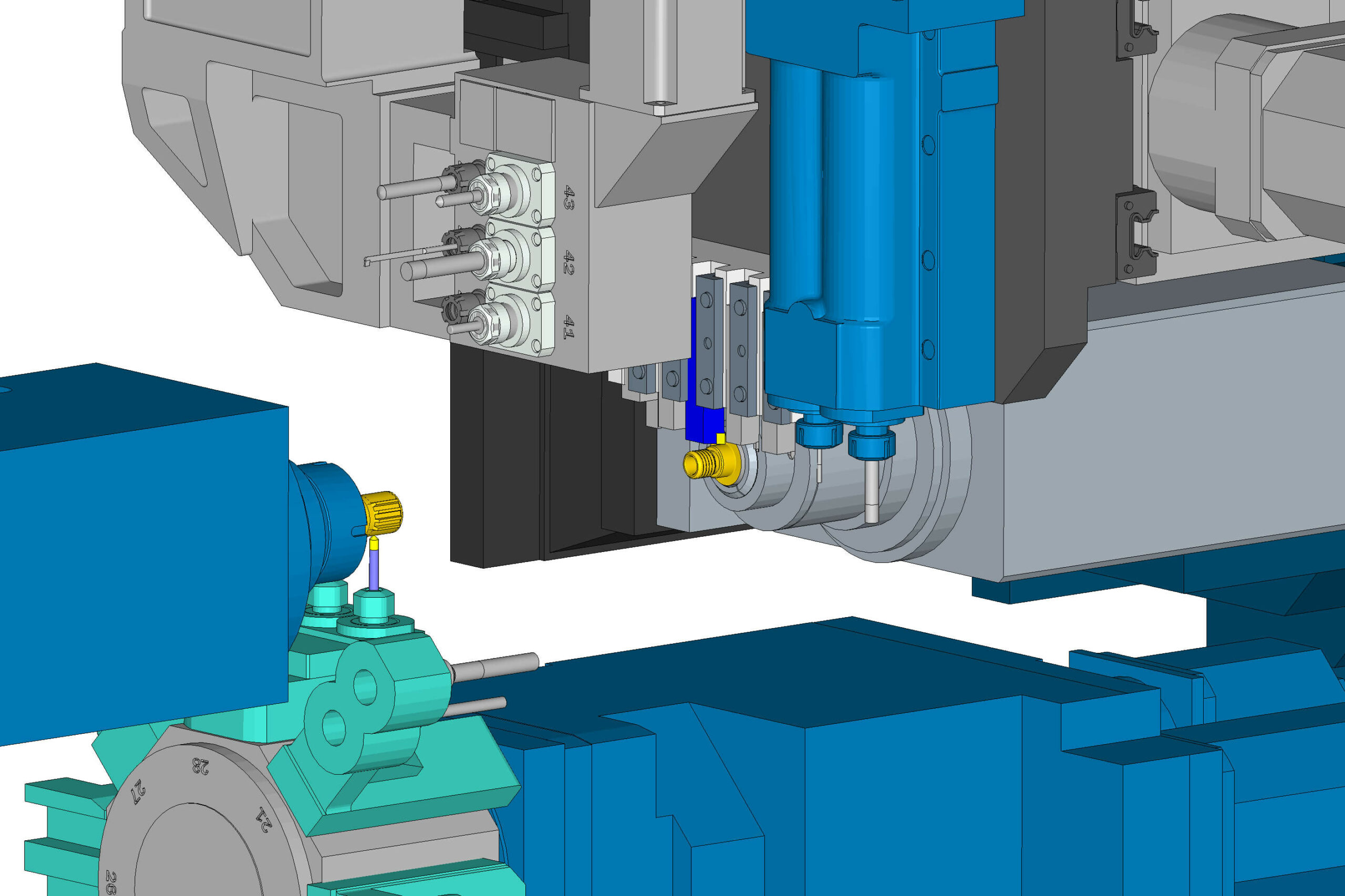

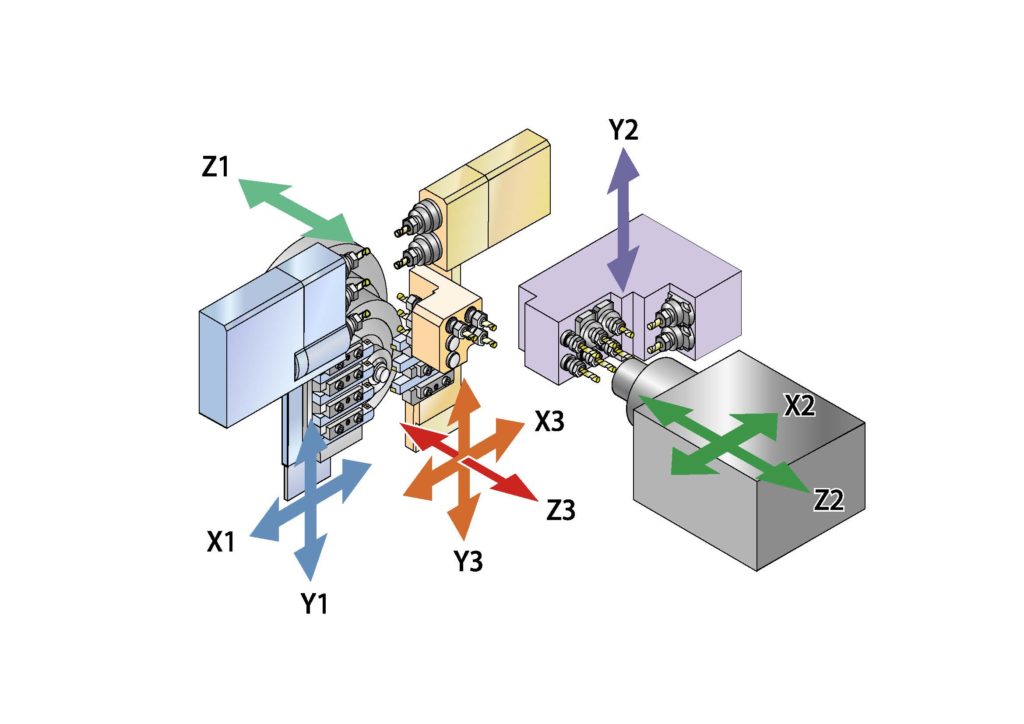

11-Axis Turret Model with 3-Channel Programming 39 Tool Capacity 45mm 56mm 67mm size models. In order to fully achieve a greater machining utilization and better production on a CNC Swiss lathe its expedient to understand. 20 - 30 an hour.

Product Development Solutions Inc 40. This enables machining of very accurate and sometimes very small parts. Swiss CAM software such as Autodesk PartMaker.

Swiss CNC machines have a small work area which can make. In contrast to a traditional CNC machine with 3 or 4 axes Swiss machines can equip. UGNX and CATIA systems have turning and milling complex CNC machining programming function modules.

Programmers are now able to create programs for machines quicker using CAM than they. Swiss machining is a specialized type of CNC machining that utilizes a sliding headstock collet and guide bushing. How to program a swiss type cnc lathe machine.

Swiss CNC machining is a specialized process to machine small high precision turned parts. CNC Lathe Mill andor Swiss Setup Machinist. A Swiss CNC machine also referred to as a Swiss automatic lathe Swiss screw machine or.

Swiss Turn Solutions provides CNC programming for most equipment and controls specializing in Swiss CNC.

Cnc Swiss Machine Capability Hartford Technologies

Understanding Swiss Type Machining Modern Machine Shop

Making Parts On A Swiss Laser Machine Production Machining

Cnc Fixed Sliding Headstock Swiss Automatic Lathes Swiss Screw Turning Centers

Swiss Lathe Cnc Machines Absolute Machine Tools

Cnc Swiss Screw Machining Cnc Lathe Cnc Milling Laser Marking

Optimizing B Axis On Gang Tool Based Swiss Machines Production Machining

The Multi Tasking Cnc Lathe Machine Swiss Type Drilling At The Brass Shaft The Hi Technology Metal Working Process With Turning Machine Control By Cnc Program Stock Photo Adobe Stock

Insights Into Cnc Programming And Machine Optimization Cutting Tool Engineering

7 Things You Should Know About Swiss Style Turning Machines

Understanding Swiss Type Machining Modern Machine Shop

Understanding Swiss Type Machining

Tsugami Bw209z 20 Mm 9 Axis Swiss Type Cnc Automatic Lathe Tsugami America

The Multi Tasking Cnc Lathe Machine Swiss Type Stock Photo Image Of Tooling Industry 188640124

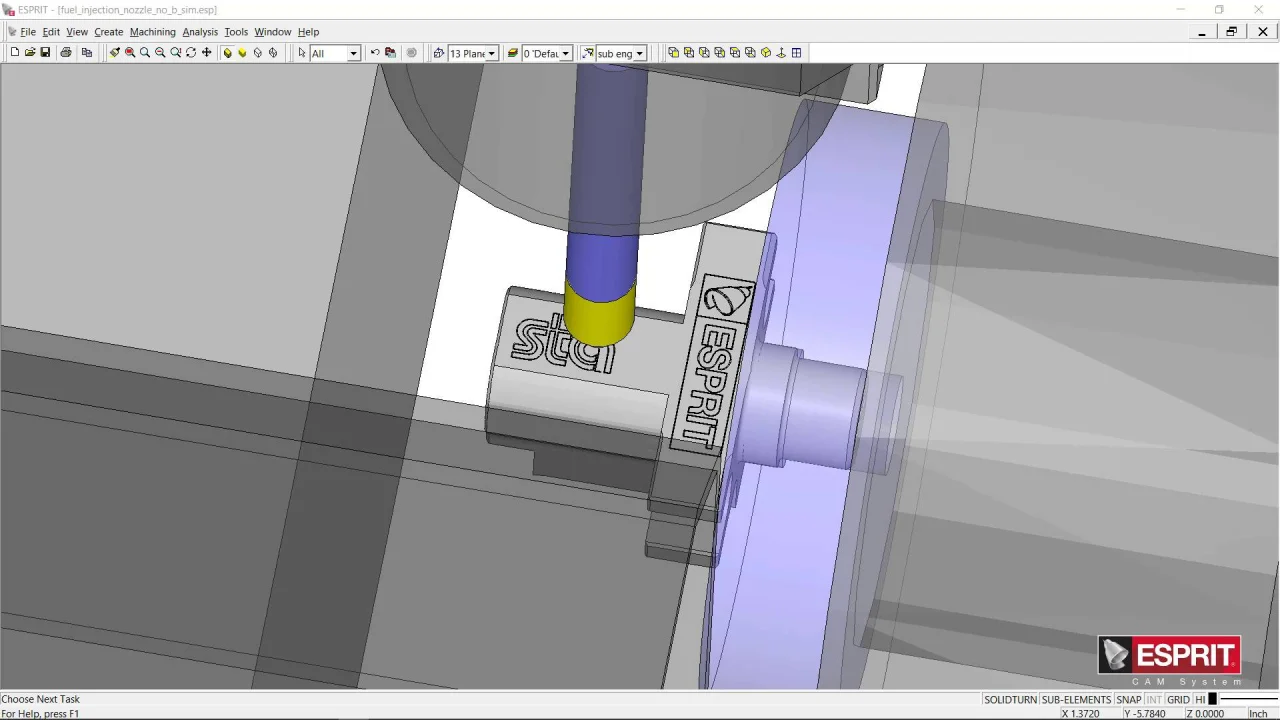

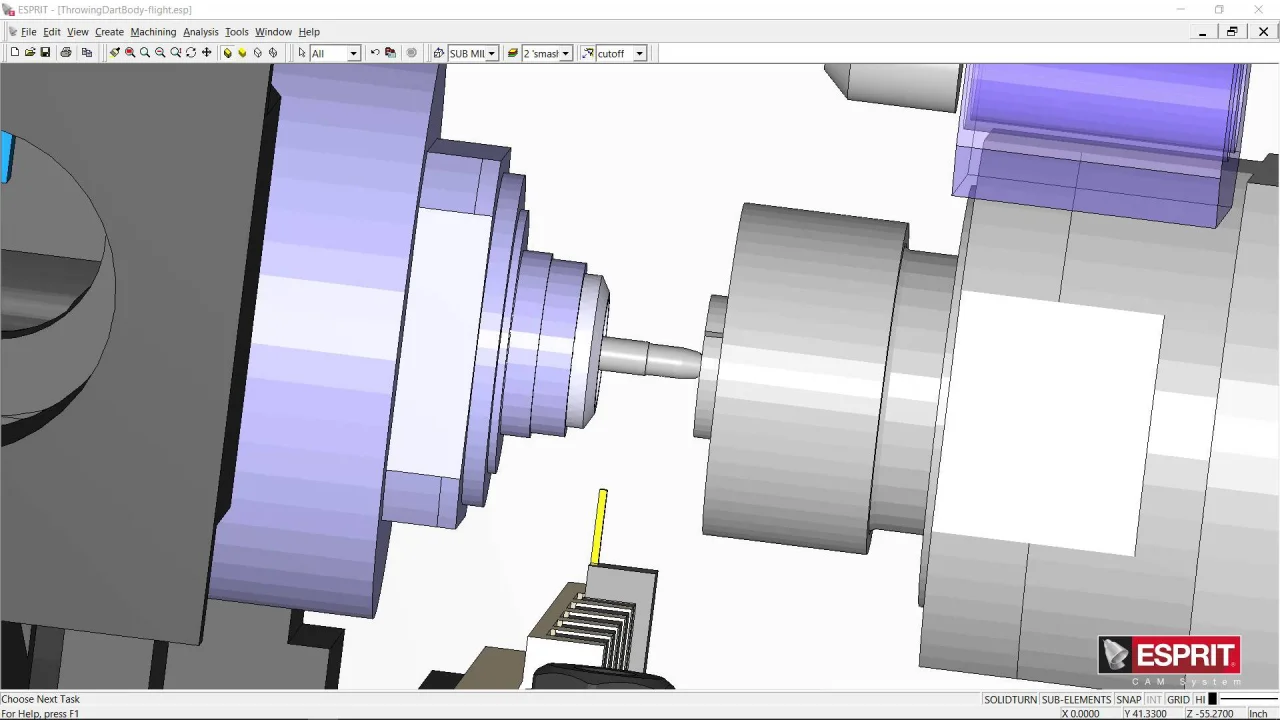

Swiss Type Machining Tuned For Swiss Type Cnc Turning Centers Programming Cycle Time Optimization And Full Machine And Process Simulation Espritcam

Cam Programming Vs Manual Programming In Medical Machining Medical Design Briefs

Swiss Type Machining Tuned For Swiss Type Cnc Turning Centers Programming Cycle Time Optimization And Full Machine And Process Simulation Espritcam

What Is A Swiss Type Lathe How Does A Swiss Lathe Work Swiss Turning Vs Conventional Turning